Filling equipment

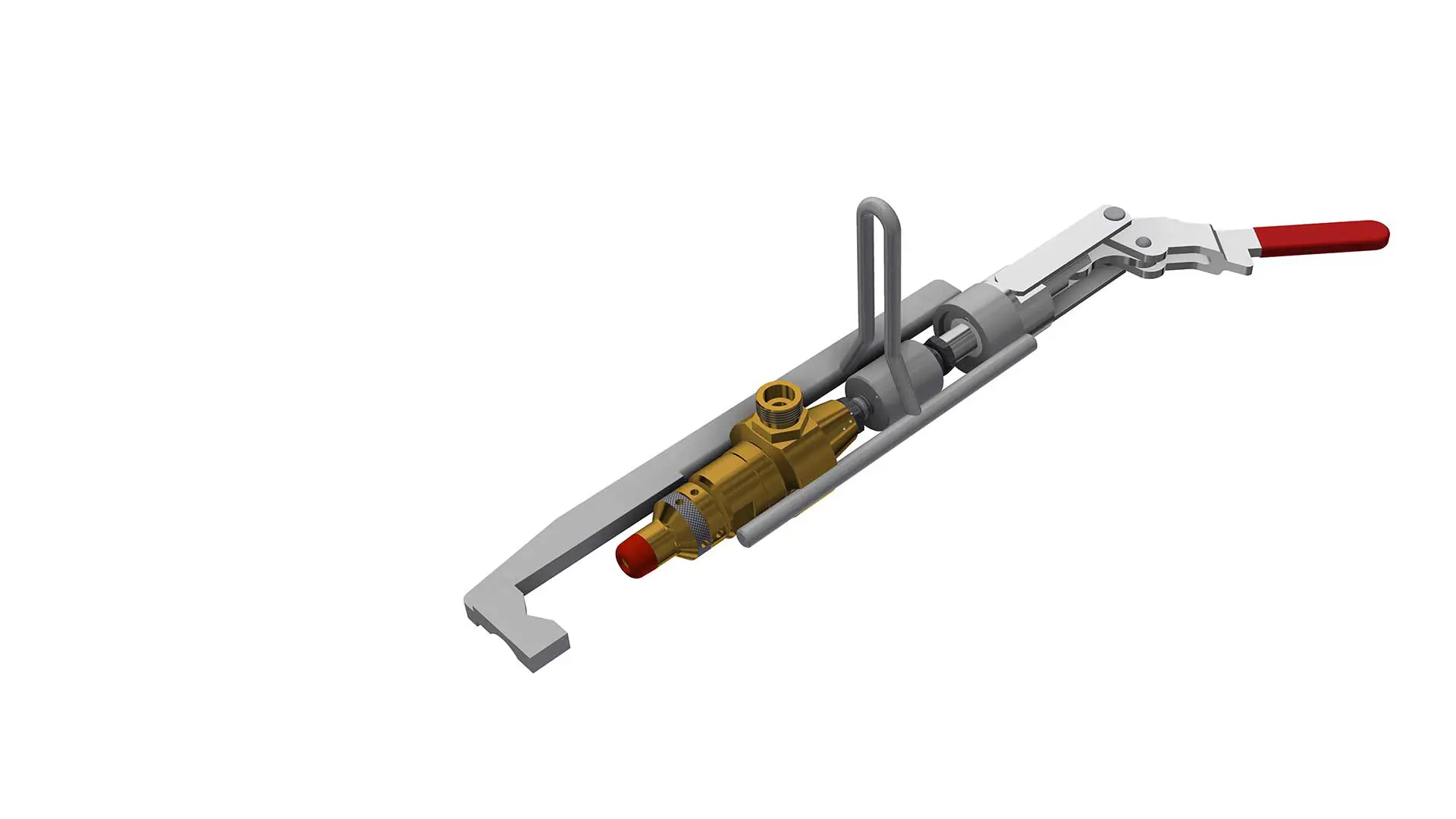

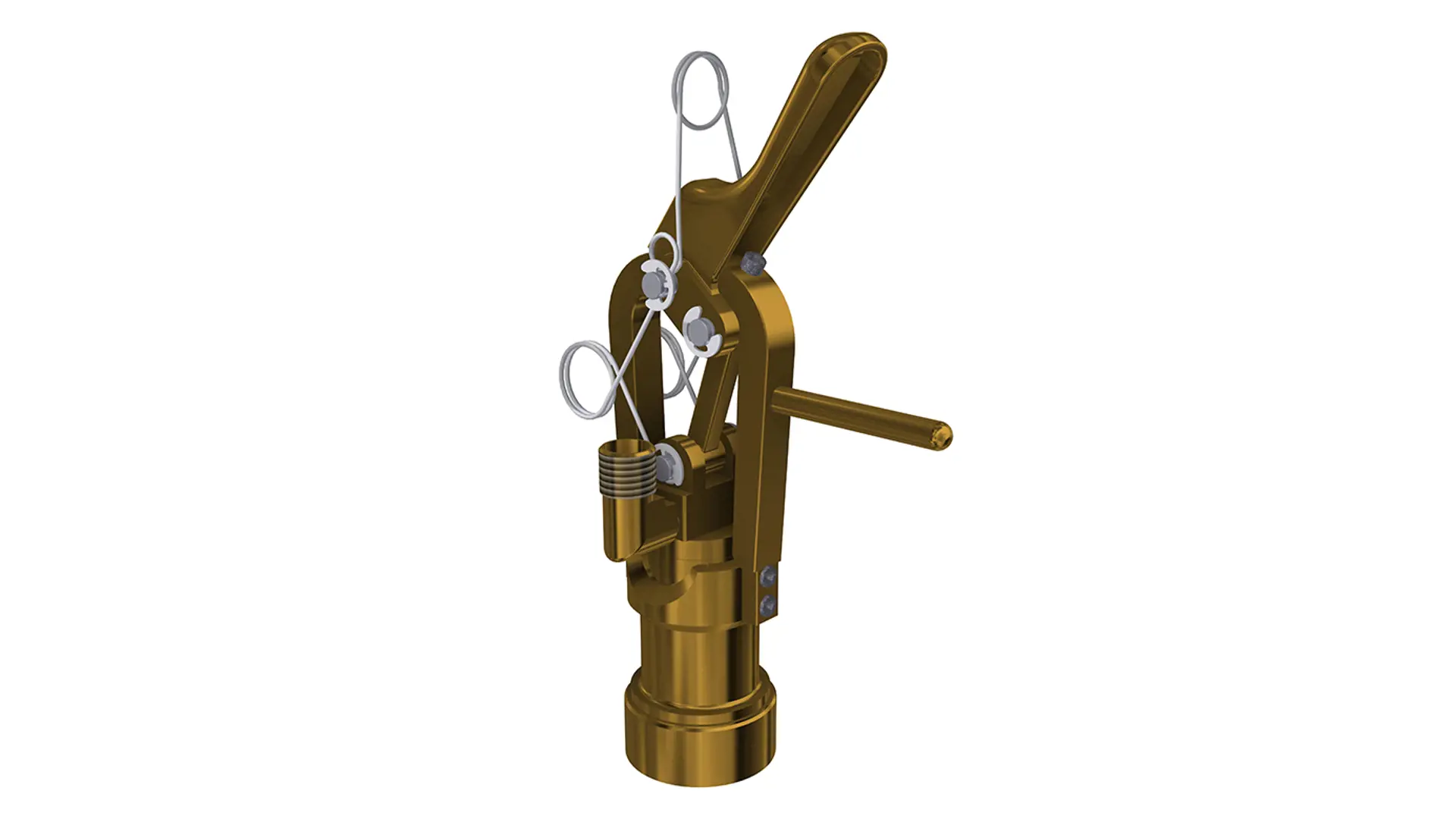

The manually operated filling head MFS is an independent unit designed for operation with a filling machine or an evacuation unit. The MFS is used for safe and accurate filling/evacuation of LPG cylinders with screw valves. It is mounted on the machine (e.g. a UFM filling machine) with a retractable spring balancer.

To connect the filling head with the cylinder valve, the operator pulls the filling head down and presses it onto the cylinder valve. Then, as the operator presses the filling head handle, a clamping hook locks the cylinder valve and the filling head, as an internal filling nozzle is connected with the cylinder valve creating an air-tight seal. When the nozzle is tightly connected to the cylinder valve, an internal gasket unseats against spring forces to open the LPG flow inside the filling head. The filling starts when the cylinder valve is opened by turning the hand wheel on the cylinder valve. This can be done manually or automatically with a valve opener/closer.

Once the filling/evacuation process is completed, the operator closes the cylinder valve and releases the filling head handle. Releasing the handle, stops the LPG flow inside the filling head and then disconnects the nozzle from the cylinder valve with a delayed operating sequence (using a spring force). As the nozzle is retracted from the cylinder valve, the clamping hook disconnects from the cylinder valve. Finally, the filling head retracts back under the spring force of the retractable spring balancer.

Benefits

-

The MFS filling head can be used for both filling and evacuation of LPG

- Sequential locking and gas flow opening features ensure a higher operating speed even for a manual operation

- Customised nozzle and hook according to the customer’s cylinder specifications ensure a perfect leak-tight connection with the cylinder valve