New results from the DecomBlades innovation project proofs that glass fibre retrieved from wind turbine blades can be processed and melted to high-quality fibre qualifying to be used in new wind turbine blades. Proving this way of using recovered glass fibres is a real breakthrough on the path to a circular wind industry.

For 20 years, private companies and research scientists have experimented with recycling blades from wind turbines that have reached the end-of-life. Now, a huge progress is being made to find recycling paths for the necessary quantities of blades, as more and more wind turbines are decommissioned.

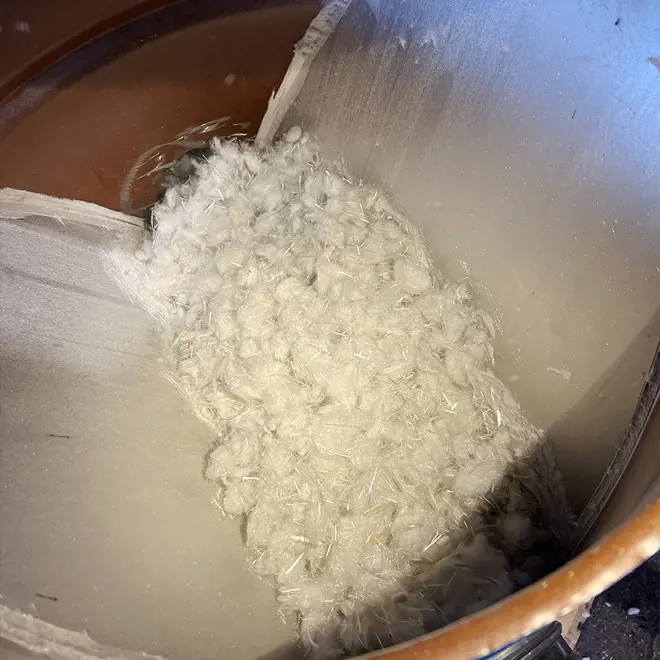

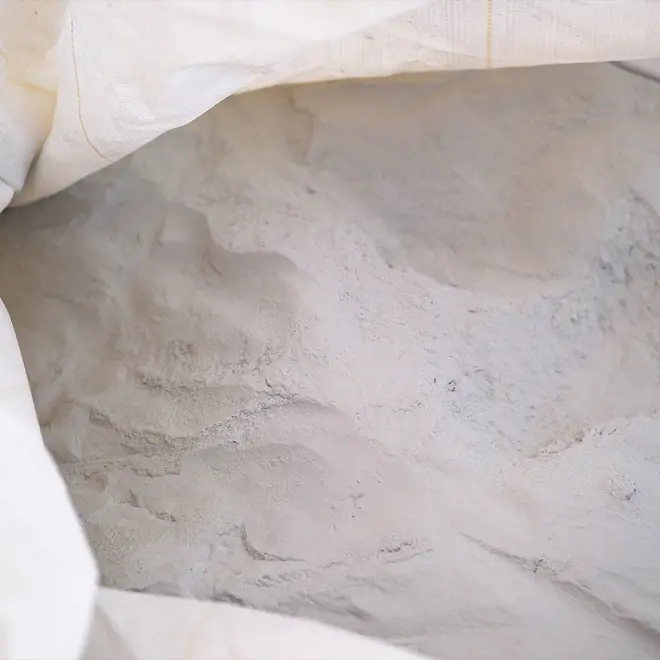

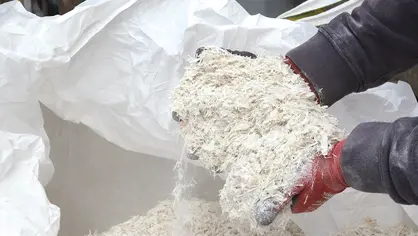

Using the largescale pyrolysis test plant developed by MAKEEN Energy, the consortium behind the DecomBlades innovation project has succeeded in extracting and processing the principal component – glass fibres – from retired 37-metre wind turbine blades to such a high quality that the material can be melted and used in the production of new wind turbine blades.

“At first attempt, we have succeeded in recovering and processing glass fibre that is suitable for inclusion in the raw material mix on a par with virgin material in the extremely sensitive glass fibre production process. We have achieved this important milestone not at laboratory scale, but at an industrial level. The process has real commercial prospects. It’s incredibly exciting to have reached this point,” says Irene Bach Velling Villadsen, Project Manager at MAKEEN Energy, the company that has developed the pyrolysis technology used in the process.

Common goals and collaboration bring about results

The partners in the DecomBlades project are MAKEEN Energy, LM Wind Power, Siemens Gamesa Renewable Energy, Vestas Wind Systems A/S, Ørsted, DTU Wind and Energy Systems, The University of Southern Denmark, HJHansen Recycling, FLSmidth and Energy Cluster Denmark. The project is funded by Innovation Fund Denmark.

In a close collaboration with subcontractors and not the least with glass fibre manufacturer 3B-Fibreglass, the project has secured a basis for creating a value chain and a sales channel for recycled fibre. This is a seminal moment in the history of wind turbine blade recycling.

"From day one, 3B-Fibreglass has been open-minded and solution-oriented. The people at 3B believed that we could make the process work, and it has been crucial to have a partner who is as committed as we are to making this happen. Thus, we have the last link in the supply chain in place: from old wind turbine blades to cleaned fibres, and, finally, the production of new blade material. And in a way that yields such high quality from the recovered glass fibre sufficient to produce new glass fibers fitting with today’s higher standards. Therefore, it is reasonable to assume that recycled glass fibre will add appreciable value to the recycling accounts,” says Irene Bach Velling Villadsen.

Successful melting

In the wake of the successful approval of the quality of the glass fibre retrieved from old wind turbine blades, the material was remelted into new glass fibres at 3B’s plant in Norway in September. Working with DTU Wind and Energy Systems, 3B and DTU will now both examine and verify the properties of the fresh glass fibres with remelted content. At the same time, the project consortium will calculate the environmental impacts (& costs) of replacing raw materials and their extraction process with glass fibre from old wind turbine blades and investigate the business opportunities derived from these.

According to John Korsgaard, Senior Director at LM Wind Power, and chairman of the DecomBlades consortium, the results achieved by applying the pyrolysis process to old blades are a further example of how innovative collaborations pay off.

“In the wind industry, we are constantly seeking novel ways to develop sustainable material flows and circular production of our products. The recent breakthrough in the project highlights the potential of reusing glass fibres from decommissioned turbine blades into the production of new fibres. This presents a significant opportunity not only for recycling companies, but also for glass fibre suppliers, even as the industry continues to face the challenge of effectively utilizing recycled glass fibers in the production of new blades. The latest results mark a significant step in closing the circular loop, transforming end-of-life blades into the raw materials needed for the production of new continuous, long glass fibres used in manufacturing wind turbine blades,” says John Korsgaard.

Read more about the innovation project at www.decomblades.dk

Questions about DecomBlades?

MAKEEN Energy

Irene Bach Velling Villadsen

Project manager

Phone: +45 87 40 30 00

ibv@makeenenergy.com

Energy Cluster Denmark

Thomas Vohs-Ahlers

Head of Membership & Sales

Phone: +45 53 89 20 50

tva@energycluster.dk