Knowledge Centre

Even the tiniest flaws affect the overall capacity of your filling plant. This guide highlights 7 of the most common profit-eating villains – plus the way to fight them.

The filling carrousel is spinning, and the flow of freshly filled cylinders on the way to your customers is constant. By all accounts, your filling system is running perfectly, so you might not pay that much attention to it.

But you should. Slowly but steadily, minor flaws invisible to the untrained eye are eating away your profit.

Minor flaws have a huge impact

High-capacity filling is all about the output. Filling systems with carrousels are optimised for maximum performance with all moving parts operating in perfect synchronisation to obtain the most efficient production flow.

As a result, even the slightest delay in an operation affects your overall plant capacity. And when you fill thousands of cylinders every day, the smallest of problems can have serious consequences.

Here are 7 of the most common profit-eating problems that our service engineers often observe:

Problem #1: The decoupling of your filling heads is too slow

Minor flaws and delays in the filling head decoupling mechanism can cause an already filled cylinder to take an additional round on the carrousel.

Result: An unnecessary extra round on the carrousel reduces your overall capacity.

Problem #2: The signal for a decoupled filling head is missing

If the photocell that detects wether the filling head has been properly decoupled is dirty or defect, an already filled cylinder might take an extra round on your carrousel.

Result: The same as for Problem #1.

Problem #3: There is a delay in the closing of your valves

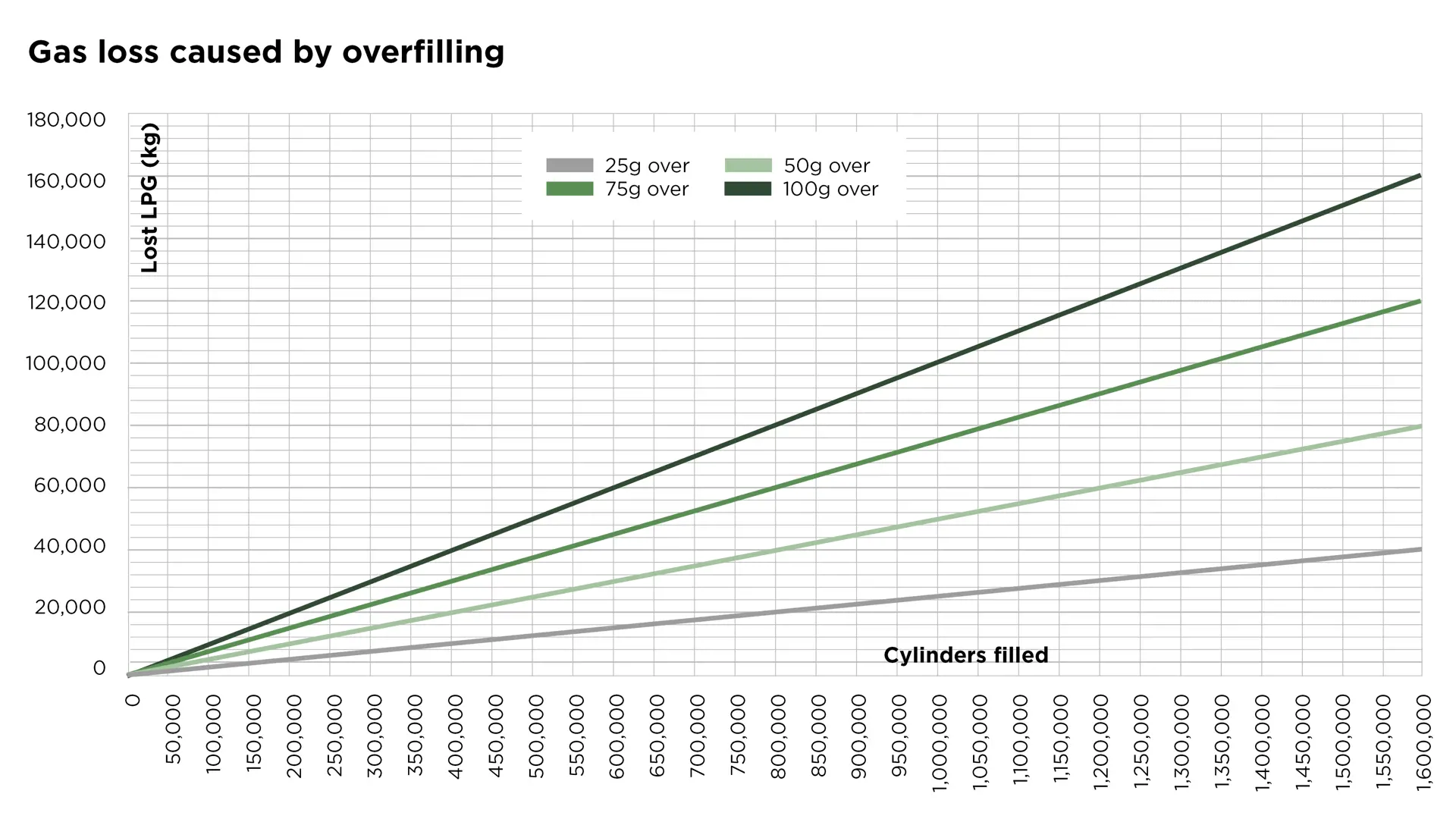

A valve that closes with just a slight delay immediately impacts your filling accuracy and typically leads to overfilling.

Result: You lose several tons of gas every year.

Problem #4: The air pressure supply is inconstant

A stable supply of compressed air ensures high performance and filling accuracy in all pneumatic mechanisms. If your supply fluctuates, it results in unsteady operation and more delays.

Result: Your filling accuracy suffers and your equipment breaks down more frequently.

Problem #5: Your carrousel speed is too high

Your filling capacity might decline if the carrousel is spinning too fast. If the speed is higher than it should be, some of your cylinders may not be completely full when they finish a round.

Result: Your cylinders need to take an extra round on the carrousel which slows down the overall capacity.

Problem #6: Your leak detector has a disturbance

A leak detector cannot begin the test until the gas sensor is clean. If the concentration of gas in the air is too high, your machine will keep trying to clean the sensor head over and over again while filled cylinders pile up.

Result: The leak detector creates a bottleneck in the filling line.

Problem #7: Your cleaning and maintenance is insufficient.

A filling system that does not get the care it needs will suffer more from the daily wear and tear and consequently not last for as long as it could have.

Result: You end up with a negative impact on financial results and need to invest in new equipment.

Download the e-book

You may never see them, but hidden imperfections can greatly harm your output and bottom line. We have gathered some of the most common things to look out for.