Case: BOC, Australia (2025)

Customer

BOC Australia, a Linde company.

The customer's challenge

While upgrading its LPG cylinder filling facility in Perth, Western Australia, BOC Australia, a Linde company, took the opportunity to digitalise data collection. The digitisation component was an important part of a broader upgrade project to improve safety and efficiency at the site and better support customers.

Our solution

An upgrade of the LPG filling operations included new filling machines, leak detector, and chain conveyor. The works also included a shift to a fully digital solution for data collection.

The outcome

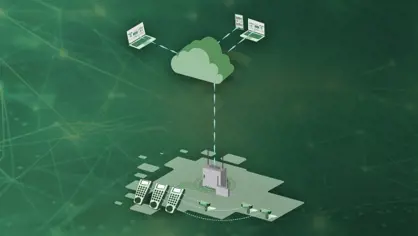

Data from the Perth facility is now accessible to Linde teams off site via the MAKEEN Gateway.

BOC, a Linde company, is the leading supplier of industrial, medical, and specialty gases. They have a strong presence in the Southern Hemisphere – including Perth, Western Australia, where we helped modernise one of their LPG filling plants.

Linde is a leading global industrial gases and engineering company. The company serves a variety of end markets such as chemicals and energy, food and beverage, electronics, healthcare, manufacturing, metals and mining. Linde's industrial gases and technologies are used in countless applications including production of clean hydrogen and carbon capture systems critical to the energy transition, life-saving medical oxygen and high-purity and specialty gases for electronics. Linde also delivers state-of-the-art gas processing solutions to support customer expansion, efficiency improvements and emissions reductions.*

*sourced from Linde.com

Optimisation, digitalisation, and centralisation

To bring their Australian operations closer together, Linde introduced the MAKEEN Gateway system at the BOC LPG cylinder filling facility in Perth. The Gateway works as a data logger, collecting information from controller units on site and tracking machine performance across the filling process.

By rolling it out at BOC, and at its ELGAS LPG facilities, Linde has brought all this data into one shared system - replacing paper-based routines and streamlining how things are done. With data now accessible at local, national, and global levels, it's easier for teams to share knowledge, support each other, and stay aligned.

And that’s just the start. The Gateway also lays the groundwork for connecting with Linde’s internal systems down the line - helping to build a smarter, more connected setup across regions.

New machines

The upgrade at the BOC plant wasn’t just about going digital – it also included a physical refresh. Several machines were replaced or upgraded to match today’s demands and boost efficiency.

The new setup includes a longer chain conveyor, six filling machines, and a customised leak detector fitted with a larger bell – tailored to handle the plant’s specific cylinder transport needs. By extending the conveyor, the elevation height can range from 750mm to 1050mm, compared to the standard of 550mm.

Another addition is a cylinder counting system on the paint line. This lets the site manager track how many cylinders are being painted – all via the Gateway platform.

Supporting ELGAS and keeping things running

To support smoother collaboration between sites, the BOC plant was also fitted with new spare parts that match those used at the ELGAS facility. This alignment helps reduce downtime and makes it easier for teams to share knowledge and resources across locations.

With both its digital systems and equipment now modernised, the BOC plant in Perth is well positioned to tap into Linde’s global know-how, run more efficient operations, and strengthen its role in the wider Australian network.