Case: Primagaz, Belgium (2024)

At Primagaz’s LPG filling plant in Tessenderlo, Belgium, efficiency is everything. With four production lines, every stoppage, every delay, and every inefficiency matters. For years, the company relied on a local- only system to track performance, but as their operations expanded, so did the need for real-time data and deeper insights.

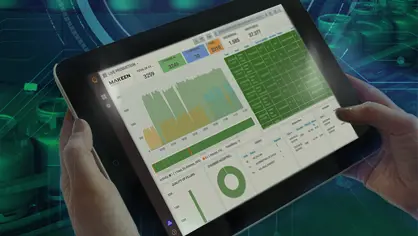

The MAKEEN Gateway is a powerful digital data logging device designed to bring LPG filling plants into the modern era of data-driven operations. By collecting and analysing data from various machines in a plant, the Gateway provides real-time insights into performance, efficiency, and potential bottlenecks. It connects equipment such as filling carousels, leak detectors, and sealing machines, tracking key metrics like cylinder throughput, rejected units, and downtime.

Primagaz first explored the MAKEEN Gateway in early 2023 after discussions with MAKEEN Energy’s Operational Excellence Specialist, Bruno Magalhães. They were looking for a modern, scalable solution to monitor their filling operations and reduce inefficiencies. The Gateway promised exactly that: a fully digital, remote-access system capable of collecting, analysing, and visualising data in real time.

By late 2023, the decision was made. Primagaz opted for a Platinum subscription, which included live performance tracking via Grafana, automated hourly reports in PowerBI, and a dedicated PowerBI workspace offering deeper analytics and full control over data. The installation took place in January 2024, and Primagaz was eager to put their new data insights to work.

Our old RCC system no longer met our expectations. It required complicated setup procedures for every new machine, which was difficult to perform from a distance. The MAKEEN Gateway offered a much better base, storage of data, and especially visualisation of the different lines and machines. Because it is web-based, it is accessible to more people.

Necessary upgrades

The first period of the integration wasn’t entirely seam-less. Shortly after implementation, our technicians found a series of inconsistencies between the real-world cylinder counts and what the system reported. They found the culprit to be the outdated existing

cabling and controller units (CUCs) that were unable to properly communicate data to the Gateway.

Rather than letting the issues slow them down, Primagaz quickly moved to upgrade the system. In July 2024, we replaced outdated equipment and implemented a crucial new feature: Overall Equipment Effectiveness (OEE) tracking.

Tracking OEE is a game-changer for operational efficiency. The Gateway allows for machine stoppages to be categorised as either planned (such as maintenance or breaks) or unplanned (such as breakdowns). Before, Primagaz’ system was not able to make this distinction, which muddied the picture when they wanted to track how much time they lost due to stoppages. The Gateway painted a clearer, more accurate picture of their plant’s performance. With this

added context, they could separate avoidable disruptions from necessary downtime, allowing for better decision-making.

“The detailed filling quality of every individual weight scale has significantly increased our overall efficiency and has become crucial for our maintenance department. Also, the error reporting gives more information to our maintenance team. The return of investment is very fast due to the numerous savings in manhours within our production and maintenance departments. We certainly want to expand the usage by integrating it with other platforms used in our company and giving other departments access to the Gateway to retrieve their information.”

We definitely recommend the MAKEEN Gateway. Finally, a good platform is available to monitor, visualise, and analyse our LPG filling activities.

Visibility and control

With the upgrades complete, the Gateway delivered exactly what Primagaz had envisioned: instant access to operational insights, anywhere and anytime.

Today, the operations and maintenance teams rely on the system’s live data monitoring platform to ensure that any issue can be addressed in real time. Meanwhile, our own technicians use PowerBI’s broader datasets to identify trends and long-term optimisation opportunities. The results have been clear: greater control, creating a basis for continuous improvement and a proactive approach to plant management.

Security was also a key factor in the transition. Primagaz opted for multifactor authentication, adding an extra layer of protection to their system. Where their previous system kept data locked on a local computer, the Gateway enables remote tracking and analytics, allowing managers to access insights from anywhere.