Finishing equipment

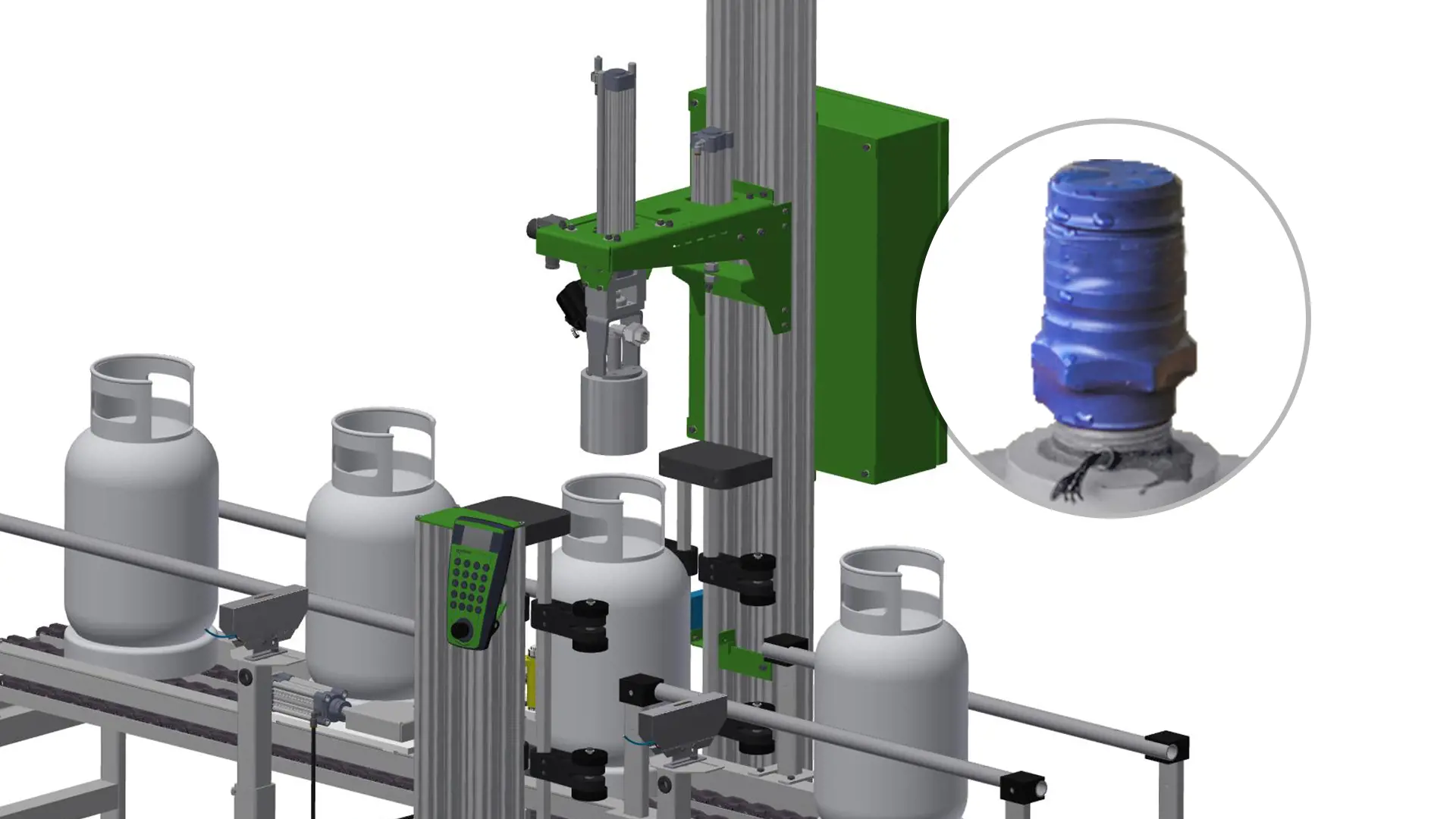

The electronically controlled valve sealing unit VSU is an independent unit designed for in-line installation in a chain conveyor.

The VSU is fully automatic and and seals cylinder valves by shrinking a plastic cap or sleeve around the valve with either steam or hot air. It is possible to choose a steam generator or an air heater as the heat source, depending on the operation conditions required.

A seal serves as an effective protection of the cylinder valve against dust, sand and other harmful particles, which may cause leakages or other damages. An unbroken seal is also a guarantee for the end user that the cylinder has been correctly filled and checked, and that it is supplied from an authorised distributor. The VSU can be used for all common valve types, if there are shrinkable plastic caps or sleeves available for the valve type in question.

Maximum safety level

- Fully automatic sealing operation (eliminates human errors)

- Ex-proof steam generator or air heater with all safety devices as required for operation in hazardous areas (optional)

- More accurate, reliable, and consistent sealing with process controls (e.g. steam/hot air flow)

Maximum production uptime

- Automatic predictive and preventive maintenance alerts with MAKEEN Energy’s Industry 4.0 Digital Solution to avoid breakdowns (optional)

- Automatic operation stops (e.g. low compressed air pressure) prevent process errors and assist in quick restarting

- Quick adjustment to different cylinder sizes and valve types

Optimised production

- Remote supervision with MAKEEN Energy’s Industry 4.0 Digital Solution for production optimisation