Supply

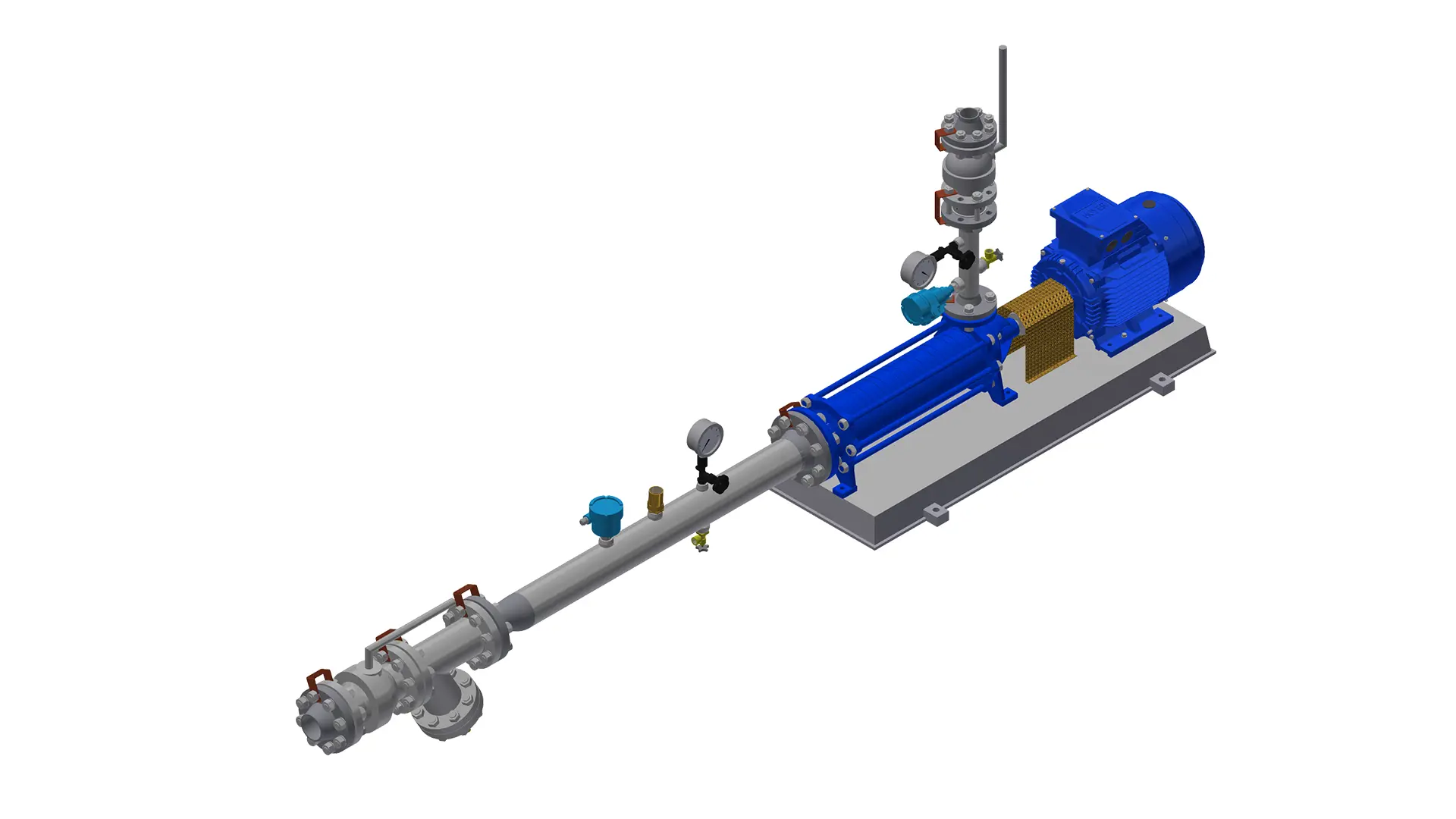

The LPG filling pump units, type FIP, are designed by MAKEEN Energy to fill LPG cylinders at high flow rates.

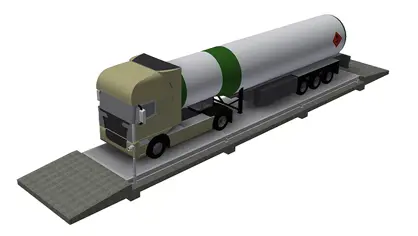

The most commonly used pump type for LPG handling is the side channel pump. This pump is available in various sizes, making it suitable for applications such as LPG cylinder filling, tank emptying, tank filling, and vaporiser feeding.

Designed as a multistage pump, the side channel pump generates higher differential pressures. It features a specialised suction stage before the pressure-generating stages, which optimises the inlet flow and enables a low Net Positive Suction Head (NPSH) value. This design makes it ideal for handling pressurised liquids like LPG. Additionally, its compact design, with a small diameter and lower rotation speed, reduces the risk of cavitation and enhances efficiency compared to centrifugal pumps.

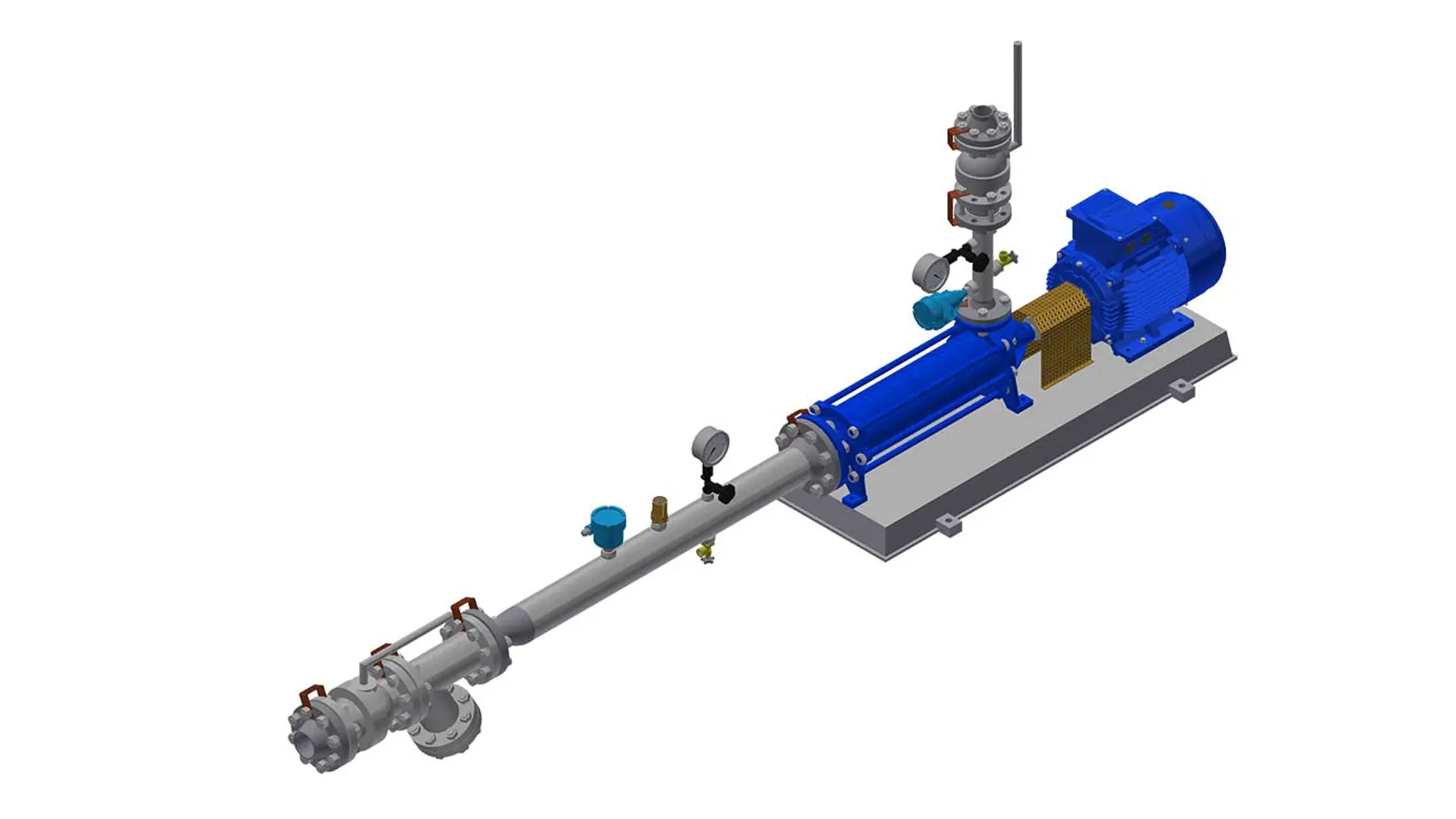

Typically, these pumps are delivered mounted on a painted steel base frame with an electric motor sized according to the required working parameters (differential pressure and flow) of the pump.

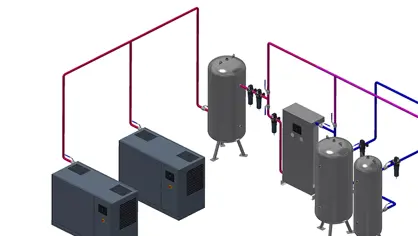

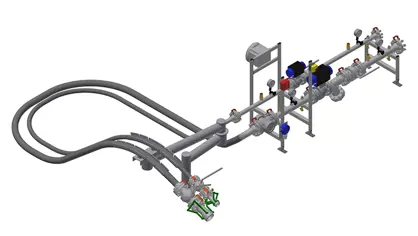

For both the inlet and outlet of the pump unit, dedicated sets of piping components, gauges, and sensors can be provided for local installation in the pump house. Cabling, start/stop switches, safety switches, fire safety sensors, and gas safety sensors are also offered for a more comprehensive solution. Moreover, pump monitoring systems are available to ensure the proper operation of the pumps.

For smaller plants, e.g. containerised filling plants, complete pump skid solutions can be delivered and customised to the actual capacity requirements.

Benefits

- Efficient operation of the filling plant with a LPG pump system tailored to the facility, optimised through analysis of piping dimensions and required flow

- Ensures stable pump operation, with MAKEEN Energy assisting in selecting the right pump by calculating pressure losses, NPSH, and pipe flow speeds

- Robustly designed and protected (e.g. painted) for long-lasting performance

- Reduces the risk of pump malfunction and prolonged downtime by utilising strainers and monitoring systems, including liquid level switches and pressure transmitters

Maximum safety level

- ATEX-certified equipment for installations in hazardous

areas