News

Back in 2009, the very first FLEXSPEED plant was built in Brazil, kicking off a new technological era in high-speed LPG filling by pushing the maximum capacity of a single filling carrousel to 4,000 cylinders per hour. Today, the FLEXSPEED technology is still unmatched and the only true high-capacity filling system in the world.

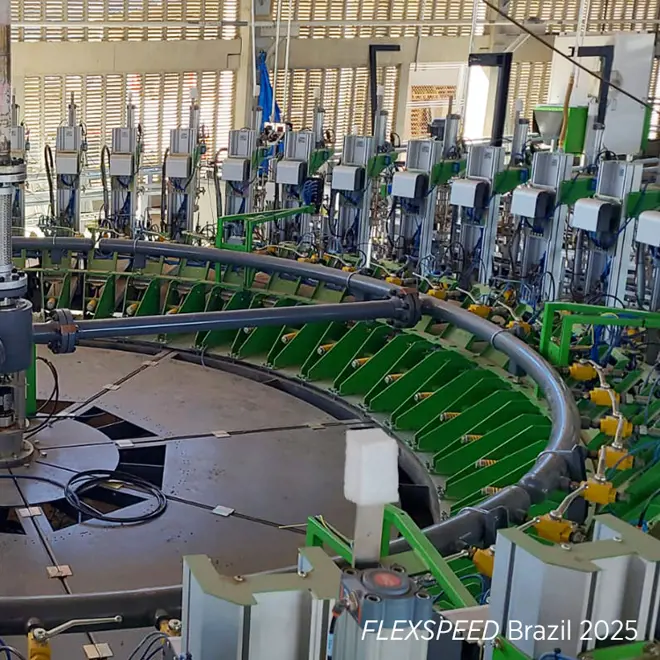

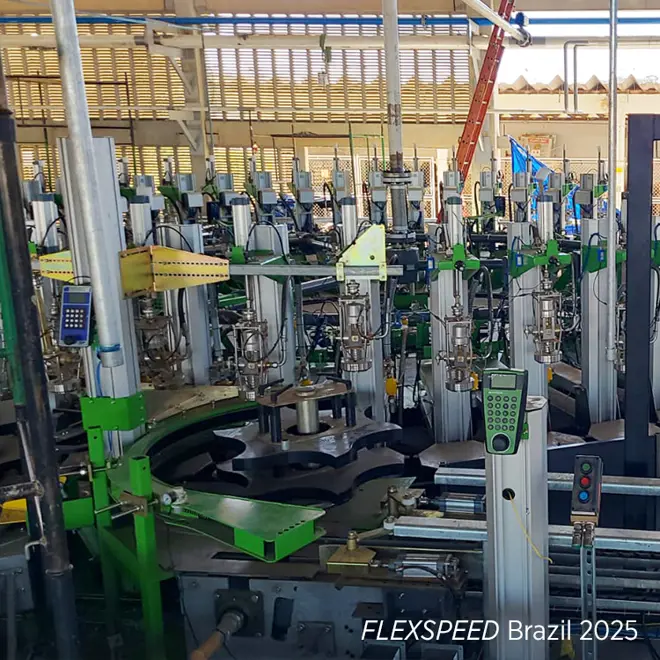

Now, the FLEXSPEED story is coming full circle, as the very first MPP (MAKEEN Product Programme) version of the FLEXSPEED is about to go into operation – also in Brazil, where it all began. Besides the fresh green colour of the machines, this new generation of the system promises even higher precision and new levels of digitalisation.

- Two FLEXSPEED carousels with 48 filling machines each

- Full peripheral equipment, including testing stations for cylinders, valves, and leakage

- Installation supervision, commissioning, and operator training

- Ongoing technical support and maintenance planning

Starting Point

To keep pace with rising LPG demand in their region, our customer in Brazil chose to replace their aging filling facility with a brand-new plant. This bold move meant building everything from scratch — new infrastructure, civil works, and roads — and equipping the site with technology designed for high-volume, reliable cylinder filling and the first MAKEEN Product Programme FLEXSPEED filling carousels to be installed.

The Project

At the heart of the new plant are two FLEXSPEED carousels, each with 48 filling machines. This marks a milestone not just for the customer, but also for MAKEEN Energy: this is the world’s first-ever FLEXSPEED installation using the next-gen MPP technology, making it a true flagship project. Today, the mechanical installation is complete, and the final utilities — compressed air and electrical work — are being prepared. Our team from Denmark will travel to Brazil at the end of September to begin commissioning, aiming to have the plant fully operational by the end of October.

Collaboration & Progress

The project has been built on close cooperation. Despite some early challenges on site, both teams have worked hand in hand to keep progress on track. The installation crew has made excellent headway, and the spirit on site remains high.

What Comes Next

Once the final utilities are ready, commissioning of the FLEXSPEED lines will begin. By the end of the year, the facility is also set to receive a third line for industrial cylinders, further expanding the plant's capacity. With this project, the customer is securing a modern, efficient, and scalable filling facility — one that will meet the region’s growing LPG demand for many years to come. And as the first MPP FLEXSPEED installation worldwide, it represents a major milestone for MAKEEN Energy as well.

"

The complexity in this project was coordinating our team’s work alongside multiple teams operating on-site, having to install our equipment while the customer simultaneously carried out all surrounding construction work including civil, electrical, and piping installations.

I would like to thank our supervision and installation teams for their dedication and professionalism. We not only met every milestone, but we were often ahead of schedule. Their performance was outstanding.

Our customer placed great trust in our expertise, listening to our recommendations and implementing them with confidence.

Artur Fonseca Project Manager CAPM, MAKEEN Energy

Learn more about FLEXSPEED

FLEXSPEED – High capacity filling

With patented handling and processing techniques, the FLEXSPEED system reaches filling capacities of more than 4,000 LPG cylinders per hour on one carousel system.

FLEXSPEED process modules

MAKEEN Energy offers various high-speed process modules with a capacity of more than 4000 cylinders/hour – just like the FLEXSPEED filling carrousel.

The story behind FLEXSPEED

How did we manage to triple the standard industry filling capacity? The inspiration came from the beverage business and dynamic bottle feed systems.

FLEXSPEED – the talk of the town

Having exceeded the limits of conventional thinking and turned the concept of gas filling upside down, FLEXSPEED is now on the lips of gas fillers everywhere.