LP Gas Solutions

For more than half a century, we have delivered close to 3,000 LPG (liquefied petroleum gas) filling facilities to customers in more than 140 countries all over the world. With our extensive experience, we are able to meet even the most demanding client requirements - from a few cylinders every day to several thousand per hour - with integrity, reliability and technological excellence.

Project-oriented mindset

We are a project-oriented corporation that supplies equipment, plants and systems for filling and maintenance of liquefied petroleum gas (LPG) cylinders. We offer our customers a full range of products and services from single machines to entire plant constructions as well as engineering, project management, after-sales packages, service contracts and facility management. We continuously develop our systems, products and services to anticipate future demands for increased capacity, efficiency and, above all, safety.

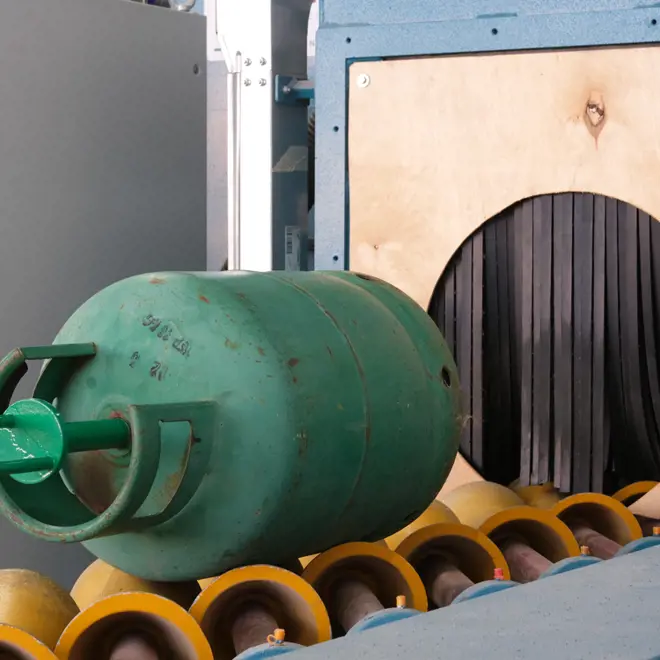

Filling systems

As an industry leader, we are proud of our LPG filling solutions and how they can match every situation, customer and need. Nothing is too small or too big. With our many years of experience, we know every corner of the LPG filling industry - and every step on the way from dreaming of new filling facilities to operating and maintaining existing equipment. And we can help you no matter which step you are about to take.

Our broad expertise makes it possible for us to handle basically everything at LPG filling plants. We can design and engineer a complete solution, manufacture every piece of equipment and install everything so it is ready to run. Whether you need help with a single component or the entire system for filling LPG cylinders, we are always ready to assist you.

To ensure that the filling facilities are always up and running - and as effectively as possible - we also have a wide range of service offers and after-sales packages. We can even take care of the daily operation with everything this involves with our facility management agreements.

Maintenance systems

Our maintenance solutions cover all the necessary equipment for repair jobs on your gas cylinders. Among other things, this includes internal cleaning and inspection, pressure test, purging, evacuation, surface treatment, hot repair of the cylinder body, shroud and foot ring straightening and valve jobs.

We also offer a selection of solutions for keeping your gas cylinders clean, attractive and safe, such as washing machines, painting booths, equipment for marking your cylinders with your commercial brand and valve seals for end-user protection.

And just as our filling systems, our maintenance solutions can be tailored to match your needs and wishes. Go to our product page to read about all our cylinder maintenance and reconditioning solutions.

Engineering global projects

MAKEEN Energy's staff of experts can make calculations and dimensioning within all fields related to installation, extensions, upgrades and renovation of filling plants, LPG storage facilities, distribution centres and maintenance plants. In addition, our staff also develops market analyses, operational analyses and efficiency tasks for customers all over the world.

Want to see our LPG solutions?

Our other business segments

Gas Equipment

Our product range contains a wide variety of gas equipment for LPG, NH3, LNG and other cryogenic gasses. Whatever your scope or requirement, we can help you reach your goals and ensure the success of your business.

Plastic Waste Recycling

With the urgent demand for environmentally friendly behavior and sustainable transformation, our EnviroTech department plays a crucial role in our responsibility agenda. Our solutions are the bridge to realising circular economies.

Customer Support

Understand and help your customers. Leave no one behind. Those are two of our core values, driving us to always help our customers perform to their highest potential.

Meet us around the world

![AIGLP 2026 Logo]()

AIGLP 39th Congress

-Buenos Aires, Argentina

Meet us at booth no. 28+29 – we look forward to seeing you! Participating at this venue: MAKEEN Gas Solutions and MAKEEN Gas Equipment

![LPG EXPO logo]()

1st Sub-Saharan LPG EXPO 2026

-Johannesburg, South Africa

We look forward to seeing you! Participating at this venue: MAKEEN Gas Solutions