An important resource

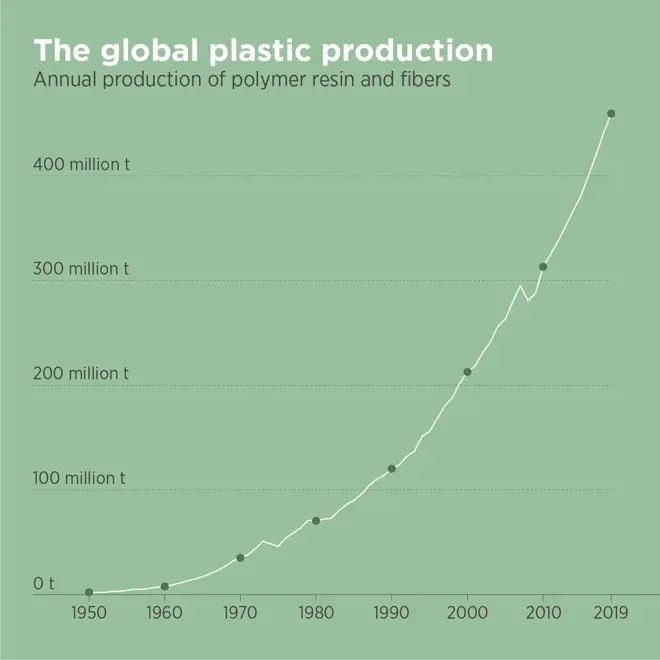

Since the mass-production of plastic took off in the 1940’s, plastic has transformed our lives to the point that it is woven into the fabric of modern society.

Due to plastic's versatility, durability, and cost-effectiveness, you find plastic in all sectors, from healthcare and transportation to food packaging and retail. Lighter vehicles made possible by plastics reduce fuel consumption and emissions. Sterile plastic medical equipment has revolutionised healthcare, preventing infections and saving countless lives. Let's not forget the convenience of packaging, preserving food, and reducing waste. It is undeniable that plastic has a vital function in today’s society and made basic amenities available to a much wider portion of the world’s population.