Plastcon – Plastic waste conversion

Our vision is a world where plastic never becomes waste. A world where every piece of plastic is valued as a resource, contributing to a circular economy.

Recycling again and again

Our Plastcon system is based on a technology known as pyrolysis – a process in which a material, in our case, plastic, is exposed to high temperatures in an oxygen-free environment. With the plastic pyrolysis technology in Plastcon, it is possible to thermally recycle plastic waste from both industry and households – and, importantly, to do so with an absolute minimum of pre-treatment. This technology allows the plastic waste to be recycled again and again.

Below, you can gain insight on the Plastcon process, and follow the plastic waste's journey step-by-step into a becoming a useful resource once again through.

1. Unwashed, presorted plastic waste

Plastcon can process and convert various types of plastic waste from both industry and households - and no pretreatment is needed using pyrolysis in chemical recycling.

2. Shredder

The shredder cuts the untreated plastic waste, including unsorted materials like organic waste and metals, into small pieces.

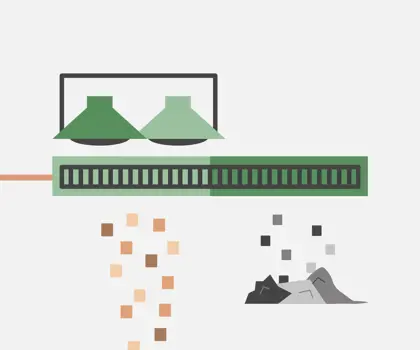

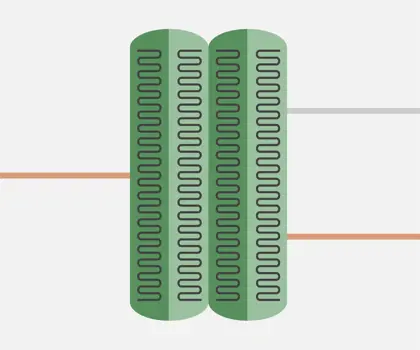

3. Sorting

The plastic feedstock, now in small pieces, goes through sorting mechanisms, including two NIR-scanners (near-infrared), removing pollution like glass, sand, stone, metal and organic materials.

4. Densifier

The plastic fragments are heated up to 200°C (392°F) and melted into a coherent mass. This decreases the volume with 60-80%.

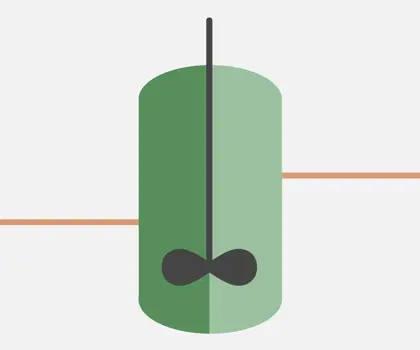

5. Pyrolysis

The reactor vaporises the mass at 400-700°C (752-1292°F) in an oxygen-free environment - the pyrolysis process is the core of our technology.

6. Codensation

Here, some of the gases from the pyrolysis process are cooled and condensed into liquid form, resulting in pyrolysis oil.

7a. Pyro gas

The non-condensable gases are collected separately, and can potentially be used as an energy source for e.g. households.

7b. Pyro oil

Approximately 75% of the plastic waste has been converted into pyrolysis oil, the desired end product, which can be used to create new plastic products.

8. New plastic for the consumer

From waste, to gas and oil, and then back to plastic. The life cycle of plastic is restored, allowing previously disposed waste to be reused in high-quality plastic products like as food packaging and medical equipment.