Case: VITOGAZ, Switzerland (2025)

Customer

VITOGAZ Switzerland AG

The customer's challenge

VITOGAZ knows how important it is to keep LPG cylinders clean. To ensure a thorough and efficient process for cleaning, they were looking to invest in a complete washing and drying system.

Our solution

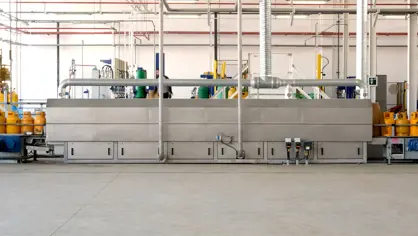

We installed a fully equipped washing- and drying system at VITOGAZ’s plant in Cornaux, Switzerland.

The outcome

Squeaky clean LPG cylinders to match the high standards of VITOGAZ.

Scope of supply

- Washing- and drying machine (incl. conveyor)

- Water treatment process (incl. sedimentation tank)

- Automatic soap dosing

- Automatic oil skimmer

- Spacer for cylinders

- Electrical panel

VITOGAZ Switzerland AG knows that when it comes to LPG cylinders, cleanliness is more than just a matter of appearance. It’s a matter of safety, quality, and customer satisfaction. That’s why, in early 2024, they reached out to us at to explore their options for upgrading their cleaning process – and we were ready to help.

Commitment to cleanliness

As the leading supplier of liquefied gas in Switzerland, VITOGAZ are well-known for their commitment to top quality which, naturally, extends to keeping LPG cylinders clean – and with good reason. When cylinders are returned from use, they often carry residues like oil, grease, dust, and dirt. Left uncleaned, these contaminants can affect the cylinders’ function, appearance, and perceived safety.

The solution? A dedicated, high-performing cleaning system that gets the job done every time.

From site visit to installed solution

To help VITOGAZ evaluate their options, we invited them to visit a customer site in Norway where a fully installed washing and drying system was already in operation. This in-person presentation gave them a clear picture of what our solution could do, from removing stubborn contaminants to drying cylinders thoroughly and efficiently.

Once they saw the system in action, they were convinced. We kicked off the project shortly after and delivered a complete washing and drying setup to their plant in Cornaux.

Installation took exactly 3 weeks and 1 day, with the system delivered and up and running on schedule.

The result was a robust and reliable solution that ensures every cylinder is properly cleaned and ready for its next use. And if one doesn’t pass the quality check? It goes straight back for another round – because clean really does matter.